Contact Ms. Thaller

Do you have a query, would you like to request a quote or start your project with us directly?

Whatever your request: Ms. Thaller is at your side every step of the way.

Over the course of our more than thirty years of company history, we have grown with the needs of our customers. Our specialty is unconventional approaches that overcome your individual challenges. Instead of problems, we see potential and develop sophisticated solutions that suit you perfectly.

Small and medium-sized companies in particular will find us a strong partner for all issues relating to plastics production. From the first meeting to the final series production, we provide you with everything from a single source. We are also accredited in accordance with the applicable ISO 9001 standards - saving you the additional costs of a quality management audit.

We know our way around technical components, medical technology, automotive, consumer goods, automation and regenerative materials: We have proven our expertise in these areas in over 1,604 successful customer projects since our company was founded.

We carry out requirements analyses, support you in selecting the right manufacturing processes and accompany you through every step of the development and production process: Including assembly, packaging, logistics and production relocation. We contribute our own ideas and experience and are always ready to change perspectives.

Don't have a concrete concept yet? We pick you up where you are right now. In a non-binding initial consultation, we will assess the current status of your project and define your goals. Our range of services includes plastic parts, mechanical components, injection molding tools, manufacturing processes, assembly equipment, automation systems and packaging.

Based on our many years of experience, we design your solution so that it really works. Before starting the project, we carry out detailed feasibility analyses, select suitable materials and manufacturing processes together with you and draw up a detailed project plan.

When working with you, we focus on a development partnership. In order to realize your idea, we believe in working together as equals to exploit its full potential. As a team, we work together to find ways and options that lead to the best possible result.

Your personal contact will be by your side throughout the entire process and will consult closely with you on all decisions. In this way, we create a solid foundation for a successful and long-term partnership.

We will find the process that best suits your requirements for your prototype. Even during the development of the prototype, we keep an eye on the subsequent series production: So you get both from a single source.

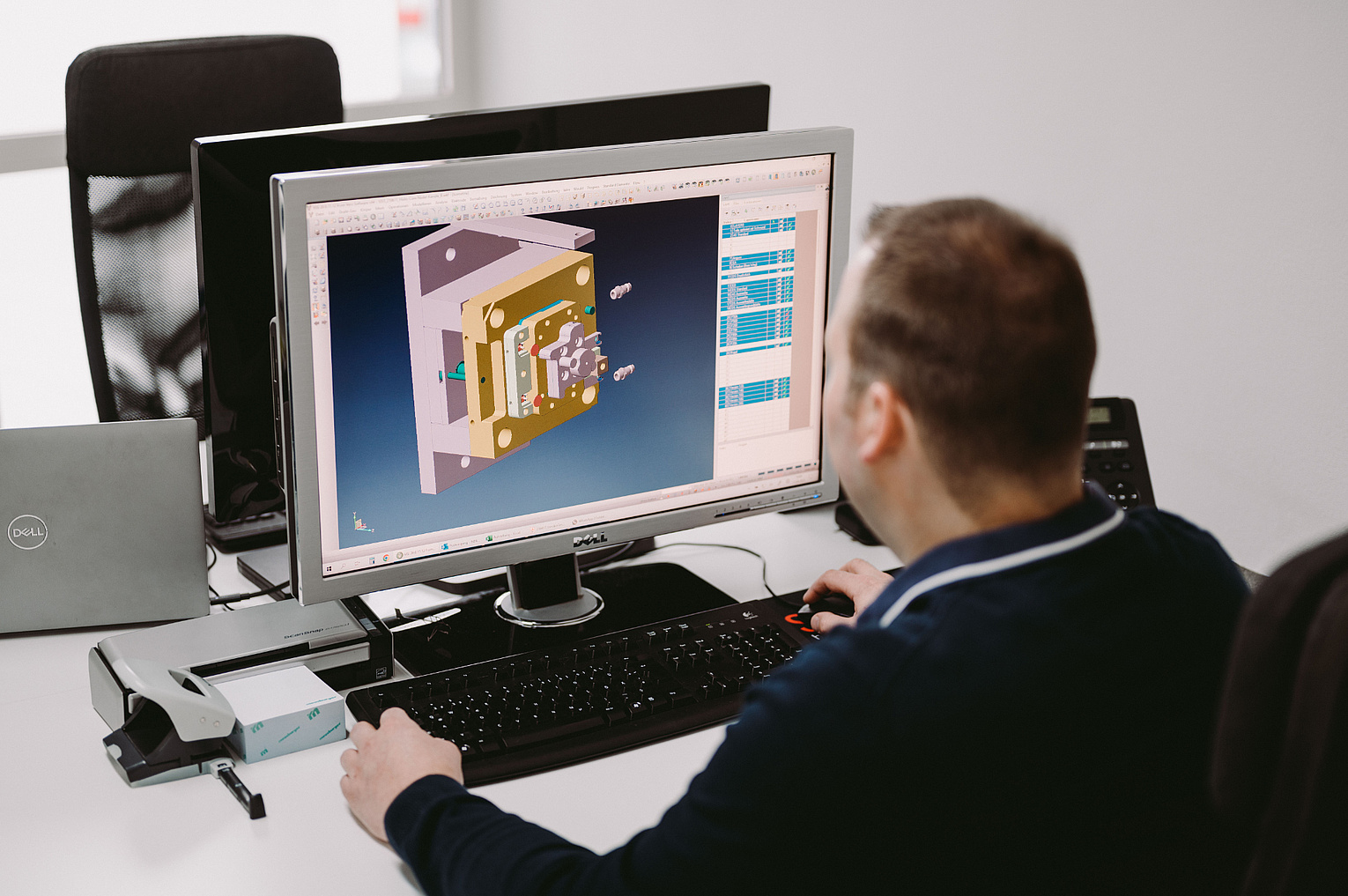

We work with Solid Works for product development and with VISI for injection molds. The result is a 3D CAD file that offers the possibility of deriving a drawing.

We take care of the design, you benefit from our many years of expertise. You receive the manufacturing rights for components and assemblies and can be sure that you will receive components that are suitable for production.

By the way: For around 90 percent of our customers, we not only design the components but also develop the prototype and carry out series production.

Many of our production and packaging processes are automated. The degree of automation in your project depends on the complexity of the product. The advantages of automation: greater process stability, faster processing, consistently high quality and a low risk of failure.

For series production, we use state-of-the-art production machines and work with robot-supported automation solutions. Constant quality controls ensure that our work lives up to its name.

Our services include order picking, assembly, storage, packaging and shipping. We produce large and small batches and are open to many possibilities: We are happy to discuss individual projects and special requirements with you.